The application range of the UV curing machine is wide, and there are also places where the UV curing machine is needed in the

furniture manufacturing industry, such as the UV varnish curing of solid wood furniture. With people's pursuit of quality of life, on the

basis of improved quality and shape of furniture products, more attention has been paid to the exquisite appearance.

Wardrobe is a common type of furniture products, mostly made of solid wood. This solid wood wood wardrobe has been finely

polished to show different qualities. In order to make the overall appearance of the wardrobe more beautiful, the wooden boards that

assemble the wardrobe are usually varnished at the beginning of production. It is to spray UV varnish on the wooden board, and then

cure it by the ultraviolet radiation cold light source of the UV curing machine.

Matters needing attention when curing UV light on wardrobe.

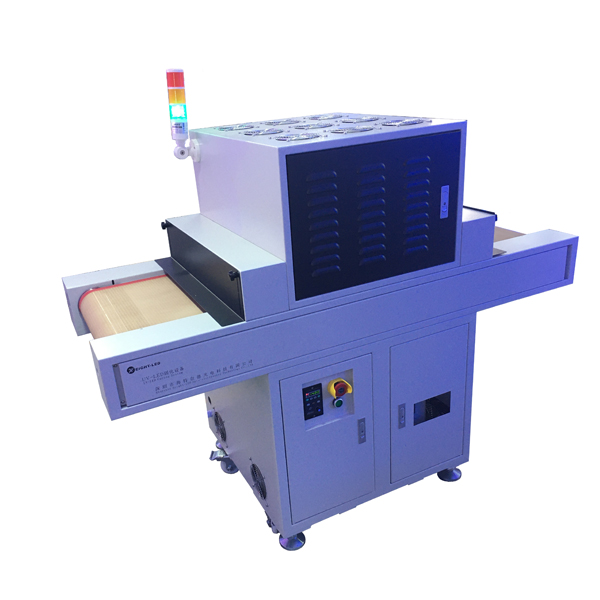

The glazing production process of the wardrobe is divided into glazing production before assembly and glazing production after

assembly. The glazing process before assembly is to apply UV varnish to each wooden board before the wooden boards of the assembled

wardrobe have not been assembled together. Spraying and curing. Then the whole installation is carried out. This kind of glazing method

can not take up space due to the decomposition of wooden blocks, which is much simpler than moving the whole wardrobe. Therefore,

automatic assembly line can be used for batch glazing.

The glazing after assembly is to spray the UV varnish on the whole and irradiate and cure with the UV curing machine after the

assembling is completed on the wooden board of the wardrobe. Because this glazing method is to glaze and cure the entire wardrobe,

both its UV varnish spraying and the UV curing head irradiation UV curing require flexible and practical supporting facilities. Such

furniture wardrobe board glazing with UV curing machine irradiation and curing UV varnish should consider environmental factors.

Wardrobe manufacturers have a lot of concerns about the technical aspects of curing UV varnish with UV curing machine on the

furniture wardrobe board. Whether the equipment can be replaced with a matching UV curing machine is often heard from customers.

So we will be concerned about the wardrobe The UV varnish used by the manufacturer is tested, and the matching degree of the

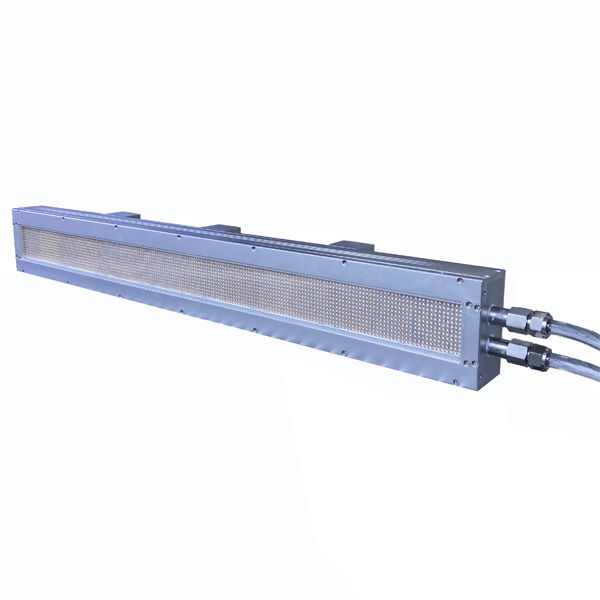

equipment that needs to be modified for the wardrobe curing is also tailored. The irradiation head, water cooling system, power supply

drive and PLC program of the UV curing machine will be customized to any size according to the needs of the wardrobe glazing to solve

your problems.

Shenzhen Height-LED is a uvled curing equipment and solution provider, which can customize products according to the specific needs

of customers.

Welcome to click on the video: Case of UV curing of wood varnish