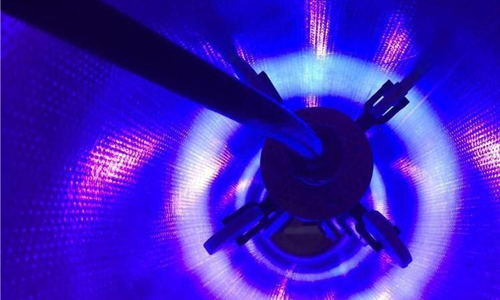

UV resin light curing is a light green transparent liquid, no curing agent and accelerator are needed for surface

coating. After coating, use the exhaust roller coating after coating, put it under a UV lamp and irradiate it with

ultraviolet light for 3-6 minutes. Fully cured. After curing, the hardness is high, the construction is simple, and it is

economical. The glue irradiated by ultraviolet light can be reused.

Features:

1.Safe and environmentally friendly.

UV resin is a solvent-free resin, with a solid content of 100% that is completely converted into a film after exposure

to light. After the film is formed, it is full and bright, and there is no harmful gas emission during the curing process,

which helps to improve the working environment and prevent air pollution.

2.high productivity

It is basically not affected by the severe cold season and can be cured quickly at room temperature.

3.Good film-forming performance

UV coating not only has high gloss, smoothness and heat resistance, water resistance, scratch resistance and other

properties.

4.Strong operability.

Because the traditional curing mechanism of UV glazing is different, it is not limited by the coating time, and the coated

object will not be cured without ultraviolet light. There is sufficient time to exhaust and remove bubbles, and it is clean

and well maintained. Unused resin can continue to be used, reducing waste and saving drug costs.

5.Can be applied by brush.

Spraying, roller coating, curtain coating and other processes, the coating can be thick or thin, and can be applied several

times for products that require film thickness.

Scope of application:

It is suitable for flat surface coating of crystal photo frame, sticking machine board, Polaroid board, furniture and so on.

BM type UV light curing resin

Light yellow transparent liquid. This product does not need to add curing agent and accelerator. It does not need to be

laminated. It is directly sprayed or drenched and cured under high-energy UV light. It is suitable for flat surface coatings

such as crystal photo frames, album covers, Polaroid boards, furniture, etc.

BM type piano baking resin

Light yellow transparent liquid This product is a three-component product. It is suitable for crystal photo frames. Kitchen

cabinet door panels. Furniture coating.

Hieght-LED engaged in UV resin light curing, if you need, welcome to leave a message.