The development of UVLED light curing technology in recent years has become more and more mature, and it has also

been widely used in various industries. Compared with traditional mercury lamps, UVLED light curing has the advantages of

fast curing, energy saving and environmental protection, and is more popular with customers. And UVLED is a cold light

source, suitable for the curing of heat-sensitive materials, and has a wider range of applications than mercury lamps.

In the printing industry, many printing materials are plastic, paper, film, etc. This type of material requires the curing

equipment not to be too hot to avoid damaging the material itself, but also requires the curing equipment to have a

certain amount of energy to quickly complete the UV ink curing. In this regard, as a cold light source curing device, UVLED

curing machine is more suitable for UV ink curing than mercury lamps. Next, Height-LED uses an example of label printing

technology that is more sensitive to heat.

Heat shrinkable film label is a kind of film label printed on plastic film or plastic tube with special ink. During the

labeling process, when heated (about 70℃), the shrinkable label will quickly follow the outer contour of the container.

Shrink, close to the surface of the container, heat shrinkable film labels mainly include shrink sleeve labels and shrink

wrap labels. The shrink sleeve label is a cylindrical label made by printing after heat shrinking as the base material. It is

easy to use and is very suitable for special-shaped containers.

The production of heat-shrinkable film labels requires high process technology. For ordinary water-based and solvent-based

inks, if the drying temperature is too high, the material will heat shrink; if the temperature is too low, the ink will not be dried

thoroughly. The process is quite complicated and the rejection rate is high. The UVLED curing machine can make the UV ink under

the action of ultraviolet energy, make the polymer material form a network cross-link in an instant, the ink cures quickly, and has

no effect on the temperature of the printing material. The unique cold curing system is very suitable for the label of heat-sensitive

materials. Production. So that UV light curing technology can solve the problem of heat shrinkable film labels.

Moreover, the UVLED curing machine has a pure ultraviolet light output, no heat radiation, infrared lamp pollution, and no

heavy metals, which are harmful substances. Compared with mercury lamps, it is more green and environmentally friendly. At

the same time, the UVLED curing machine saves energy consumption, and the energy consumption of the UVLED curing

machine is only mercury lamps. About 10% of the lamp, the service life is about 20 times that of the mercury lamp. This is why

in recent years, more and more customers have changed the mercury lamp production line to the UVLED curing production line.

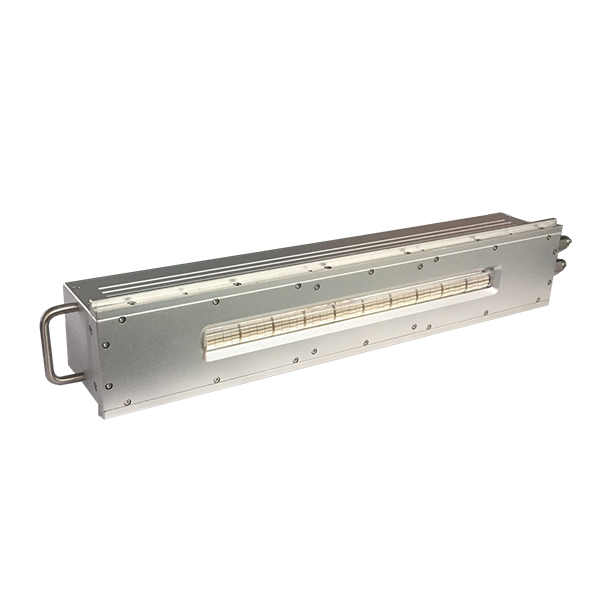

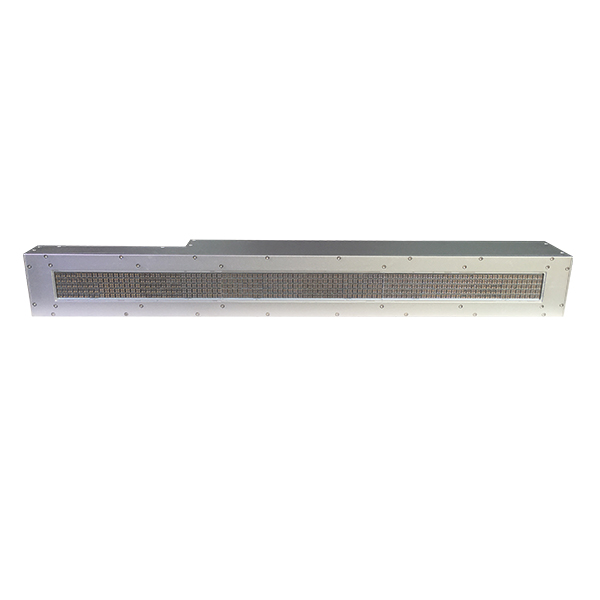

As a professional manufacturer of UVLED curing equipment, Shenzhen Height-LED has rich curing experience and can

customize suitable UVLED curing machines according to the customer's process. Welcome to consult.